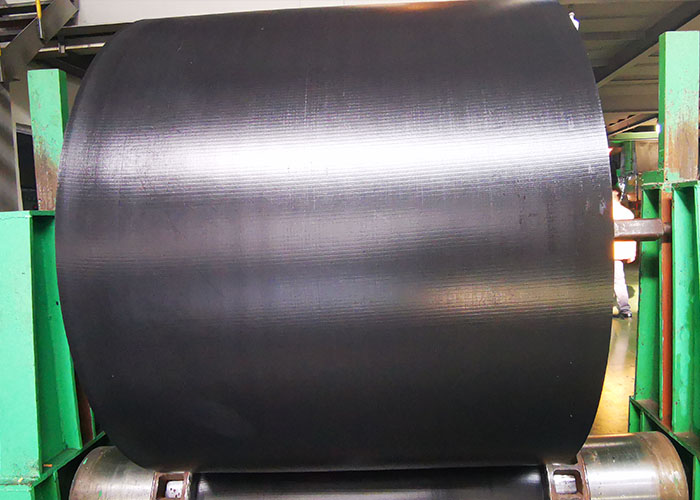

Product Features:

The product consists of solid woven fabric dipped in PVC paste and adding PVC or PVG cover which are combined together by the extrusion machine or the vulcanization press depends on the special request of the client . The belt has good flame resistant and anti-static properties, with high tensile strength in proportion to weight, good integrity and no delimitation, excellent impact and rip resistance. The belt is much suitable to service in the conditions needing fire resistant and antistatic properties as coal mines, power stations, chemical and metallurgy

Standards: MT914, BS3289 and HG2805 ,DIN22109,AS4606,BS3289,BC158

Features

· Low stretch

· Low maintenance

· Anti-static

· Flexible

· Lightweight

· Impervious to moisture, acids, oils, gases, sunlight

· Excellent fastener holding

· Excellent resistance to tearing, peeling and impact

· Endless belt splicing

· Special wear resistant edge design

PVG stands for the solid woven belt with PVG cover (nitrile rubber)

PVG type is covered with covers mainly composed of rubber, which further improves the troughability, resistance to wetness and slip, resistance to low temperature, elongation and wear resistance of the belt. Both top and bottom cover are PVG, the belt can be used to carry materials mixing some water at the slope no more than 20°,elongate life of belt

Characteristics

· Anti slide caused by wetness good climbing capacity

· Low-temperature resistant

· Good elasticity, anti-impact

· Low elongation at rated load ,suitable for long distance conveying

· Tear resistant, good flexing capacity

· Long service life

Applications:

· Especially suitable for material conveying at inflammable of underground coal mines.

· PVC is suitable for applications in dry conditions at a slope angle of no greater than 16 degrees.

· PVGis suitable for applications at a slope angle of less than 20 degrees,

thickness can be 1 to 8 mm.

also suitable for

a variety of specialist applications, including bucket elevators and

similar installations where take-up is limited. Other applicationspecific belts can be designed and custom built with the assistance

of a Fenner Dunlop engineer, ensuring the correct selection of belt

construction and covers every time.

Technical Specifications For Reference